Simulating Success: Mastering Crystallization with GPROMS

I'm excited to kick off this blog series with an introduction to GPROMS, but I'll keep it brief because things are moving quickly, and I want to share one of my current experiences with Siemens GPROMS simulations in pharmaceutical engineering learning.

GPROMS FormulatedProducts is Siemens' modelling platform for the integrated digital design of robust formulated products and their manufacturing processes. It empowers scientists and engineers to efficiently evaluate formulations, assess risk, and optimize both formulation and manufacturing processes for a wide range of applications. You can visit the GPROMS website by Siemens to learn more. Siemens also offers a learning platform called Training at Siemens, which you can subscribe to with your university email if your university or institution is a partner. In the case of Strathclyde, they offer very useful courses to master this great software.

During my coursework in my master's program, I needed to propose a continuous crystallization process design for a given model compound. The challenge here was that I did not know the compound name and needed to first understand the compound and the system without resorting to literature reviews or knowing the structure of this compound. The goal was to produce a report proposing a robust small-scale continuous crystallization setup capable of producing at least 100 g/l.hr of the crystalline product with well-defined product quality.

After designing a continuous oscillatory baffled crystallizer (COBC) with well-defined parameters and process design, I reached the point where my coursework should be finished. However, I thought, why not use GPROMS to simulate this developed process and validate it? This is a prime example of how GPROMS can be used as a learning tool. You don't need a COBC setup or to manipulate this setup to understand how things work. You can practice your theoretical understanding directly from your computer and see how experimental or physical systems will perform.

However, I encountered many problems when attempting to run simulations using a PFR (Plug Flow Reactor) continuous crystallizer. PFR is a type of reactor where the reactants flow through a tube, and mixing primarily occurs through axial flow. Despite its common use in chemical engineering for continuous processes, it presented challenges in GPROMS software.

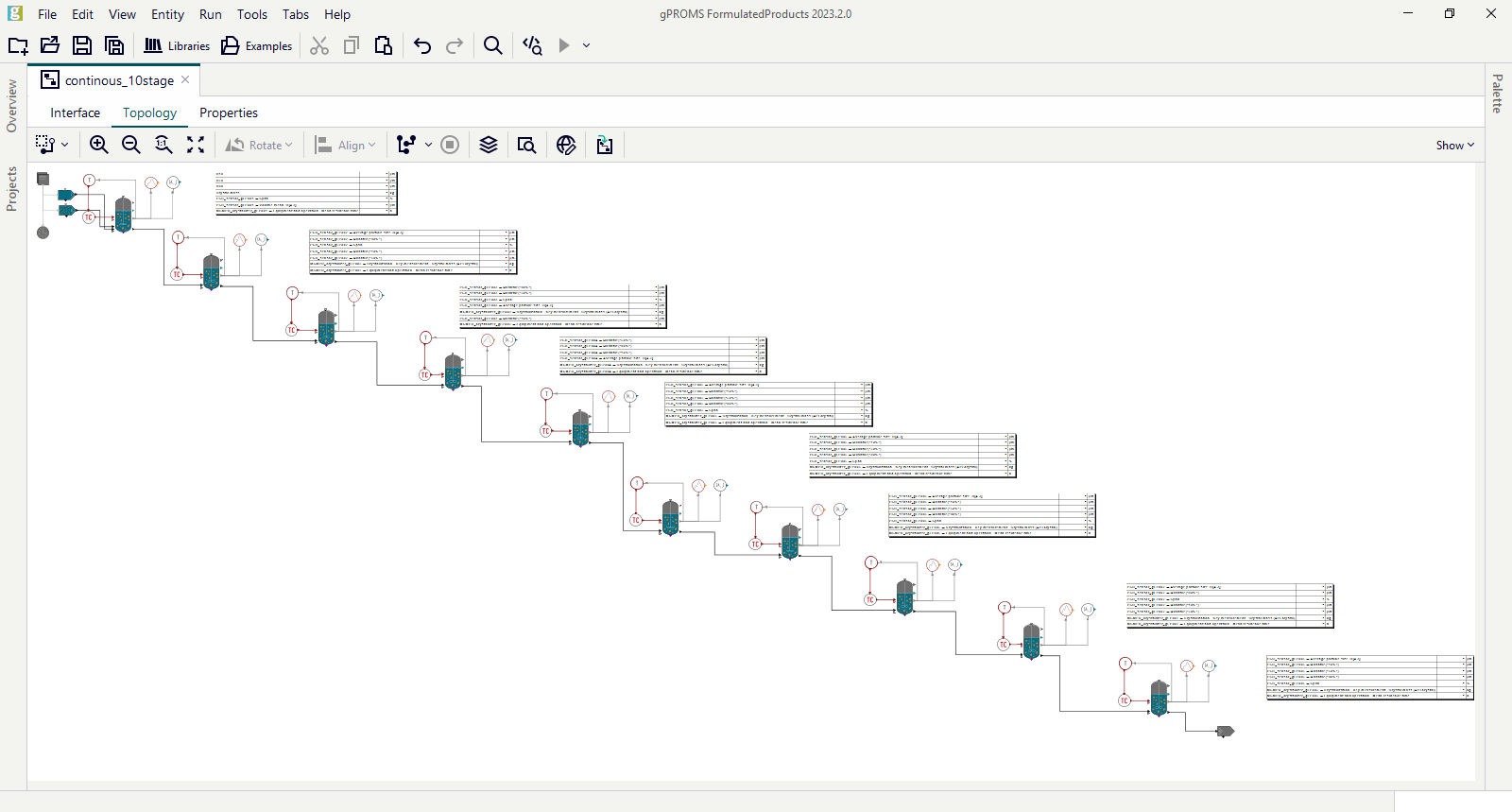

That's why Dr. Brown recommended maintaining the same crystallization system parameters but employing a 10-step MSMPR (Mixed Suspension Mixed Product Removal) approach. MSMPR is a crystallization technique where crystals are suspended in the solution and continuously removed to maintain a steady state. This approach provided me with deeper insights into the continuous crystallization process, its digital design, and honed my problem-solving skills.

By applying what you learn in real-world problems and delving into the details and complexities of different processes, I must admit that this has been one of the most transformative learning experiences I've had, all thanks to GPROMS and of course Dr. Cameron Brown.